Asset Integrity Services

At Kova Engineering (Saskatchewan) Ltd., we provide specialized asset integrity services designed to ensure the safety, reliability, and longevity of your critical process equipment. Our solutions are tailored to manage the integrity of assets throughout their lifecycle, from design and installation to operation and maintenance. Our certified engineers, technologists, and technicians help clients minimize equipment breakdowns which avoids costly downtime and extends the service life of equipment. We have been the province’s leading inspection and testing services provider for over 30 years, catering to asset integrity management needs of our clients in a variety of industries.

Our expert team at Kova Engineering (Saskatchewan) Ltd. provides a holistic approach to our clients that integrates engineering, design, inspection, and Non-Destructive Testing (NDT) techniques. We collaborate closely with our clients to design maintenance programs that align with each client’s unique requirements. Whether integrating asset integrity solutions into existing systems or creating new ones, we ensure optimal asset performance.

Expertise in Asset Integrity Services

Kova Engineering (Saskatchewan) Ltd.’s asset integrity solutions are built around ensuring assets perform their required functions efficiently and effectively while maintaining the highest standards of safety and environmental protection. We achieve this by implementing rigorous asset integrity activities that ensure people, systems, processes, and resources are fit for purpose throughout the assets lifecycle. Our risk-based methodologies focus on evaluating risk criticality for each asset, identifying critical equipment, and recommending actions to mitigate potential risks.

Our team of certified engineers, technologists, and technicians possess in-depth knowledge of applicable codes and standards including CSA, ASME, API, ANSI, ISO, and NBC. This knowledge, combined with our expertise in mechanical, metallurgical and structural engineering, assists our clients in designing, constructing, and operating their facilities safely and efficiently. We also ensure compliance with all relevant regulatory bodies, helping our clients meet their legal and safety obligations.

Engineering & Integrity Management

Our engineering services extend beyond inspection. We deliver engineering-driven solutions that help you not only identify issues but proactively manage asset health and performance over the long term. Our engineering expertise allows us to interpret inspection data within the broader context of asset lifecycle management, helping you make informed decisions about repairs, upgrades and strategic maintenance planning. Our Engineering Expertise Includes:

- Mechanical, structural and metallurgical engineering assessments tailored to asset type, service conditions and operational history.

- Assessment of loading conditions, operating stresses, environmental exposure and historical data to predict degradation rates.

- Development of engineered remediation plans — including repair, retrofit or replacement strategies based on lifecycle cost analysis.

- Design of custom maintenance programs, transitioning from time-based reactive approaches to data-driven predictive and condition-based strategies.

- Seamless integration with existing CMMS platforms or development of standalone integrity management systems for smaller operators.

Inspection & Testing

At the core of our Asset Integrity Services, inspection and testing form the critical first line of defense against asset failure. Through systematic assessments and advanced non-destructive testing (NDT) methods, we gather precise data about the condition and performance of your equipment — giving you the insight needed to make informed decisions. Our inspection programs are designed to detect early signs of material degradation, structural fatigue and mechanical wear, ensuring that potential issues are identified and addressed before they compromise safety, production or regulatory compliance. Whether conducting routine condition assessments or targeted evaluations for critical equipment, we deliver both technical accuracy and actionable results to support long-term asset reliability. Services Offered:

- Visual inspections

- Non-Destructive Testing (NDT)

- Quality Assurance and Quality Control (QA/QC) assessments

- Load and proof testing

- Dielectric testing

- Material verification

- Dimensional verification

Asset Performance & Risk Assessment

Effective asset integrity management requires more than inspections. It requires a deep understanding of operational risks, failure mechanisms and performance degradation over time. Effective asset performance management is rooted in data-driven risk assessment, identifying the equipment most critical to your operations and predicting potential failure modes before they occur.

At Kova Engineering, we apply advanced engineering analysis to evaluate each asset’s structural, mechanical and material condition within the context of its actual operating environment. This allows us to prioritize maintenance efforts, recommend targeted interventions and support your team in developing cost-effective life extension strategies — all while maintaining regulatory compliance and operational safety. Our Analytical Services Include:

- Risk-based equipment criticality analysis

- Fitness-for-service (FFS) evaluations

- Performance monitoring and asset life extension strategies

- Vibration analysis, fatigue assessment and corrosion rate prediction

- Compliance audits and regulatory documentation support

Industries & Assets We Serve

Our Asset Integrity Services are not one-size-fits-all; they are carefully designed to fit the operational realities of each industry and facility type. Our technical expertise spans:

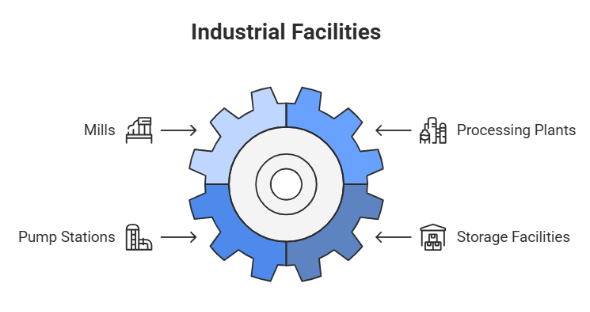

(i) Industrial Facilities

At Kova Engineering, we understand that for industrial facilities, asset integrity is directly tied to production continuity and environmental compliance. A single unexpected equipment failure can cascade into prolonged downtime, missed production targets, environmental incidents and regulatory penalties. That’s why our approach emphasizes early detection of degradation mechanisms, supported by data-driven performance analysis and risk-based prioritization of inspection and maintenance efforts. Our services cover:

- Mills

- Processing plants

- Pump stations

- Storage facilities

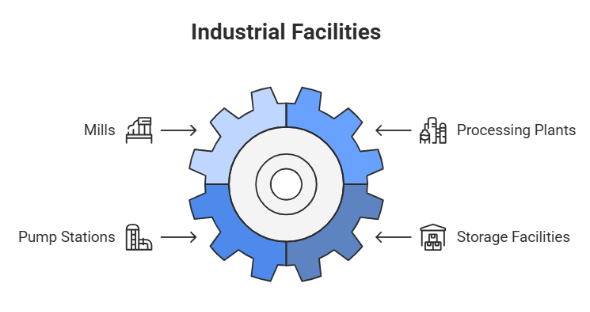

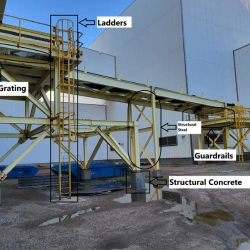

(ii) Structural Assets

Structural assets support equipment loads, personnel access, material storage and environmental protection. At Kova Engineering, we apply structural engineering expertise alongside hands-on inspection and testing to ensure structural assets maintain their integrity throughout their service life. We provide comprehensive solutions for structural assets, such as:

- Structural steel and reinforced concrete structures

- Glued-laminated timber components

- Roofing and cladding systems

- Structural hangers and supports

- Access systems (ladders, stairs, guardrails)

- Lighting and suspended equipment (e.g., monorail cranes)

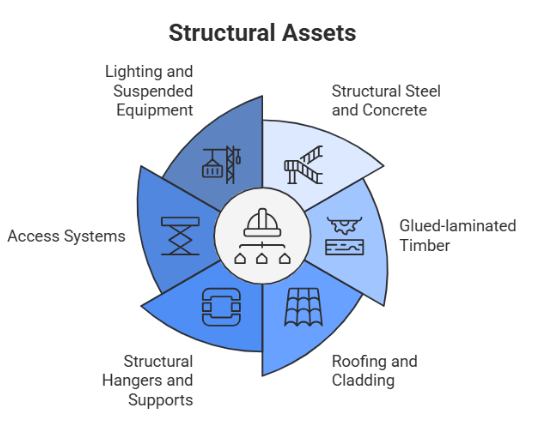

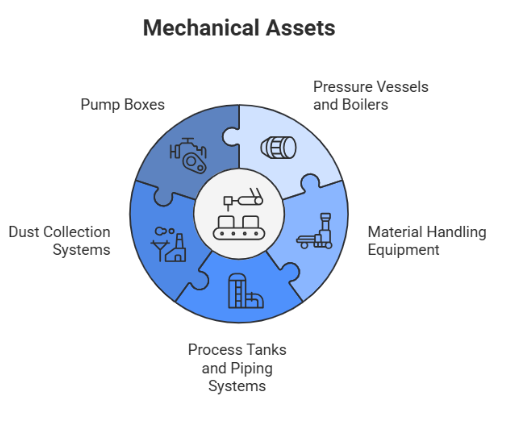

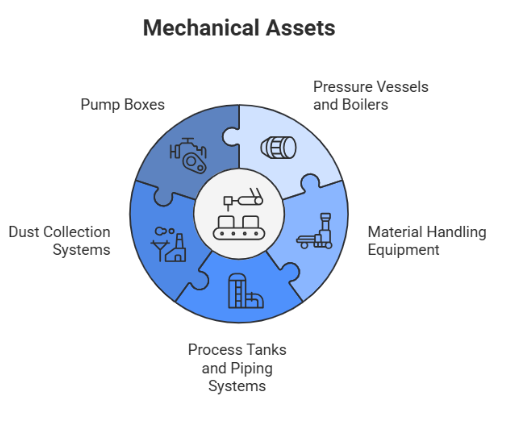

(iii) Mechanical Assets

Mechanical assets are responsible for material handling, fluid movement, pressure containment and product processing. Effective Asset Integrity Service for mechanical equipment demands deep technical understanding of mechanical failure modes, including corrosion, erosion, fatigue cracking, pressure cycling and misalignment. At Kova Engineering, our mechanical asset integrity programs blend non-destructive testing, performance monitoring and engineering analysis to provide a full understanding of asset condition and remaining life. We provide comprehensive solutions for mechanical assets, such as:

- Pressure vessels and boilers

- Material handling equipment (conveyors, screw conveyors)

- Process tanks and piping systems

- Dust collection systems (bag houses)

- Pump boxes and related process equipment

Get Started With Asset Integrity Services

Contact Kova Engineering (Saskatchewan) Ltd. to develop a customized Asset Integrity Management Program for your facility.

Get Started With Asset Integrity Services

Contact Kova Engineering (Saskatchewan) Ltd. to develop a customized Asset Integrity Management Program for your facility.

Why Choose Us for Asset Integrity Services?

- 30+ years of experience delivering asset integrity services to industrial operators across Saskatchewan.

- Multidisciplinary team of certified engineers, technologists and technicians, ensuring technical accuracy across all inspections and assessments.

- Extensive knowledge of CSA, ASME, API, ANSI, ISO and NBC standards, ensuring full regulatory compliance in all jurisdictions.

- Proven expertise in risk-based inspection (RBI), fitness-for-service (FFS) assessments and root cause failure analysis (RCFA).

- Comprehensive approach, integrating inspection results with engineering analysis and lifecycle cost considerations to provide actionable insights.

- Client-first philosophy, delivering practical solutions tailored to each asset’s service environment, operating history and future reliability needs.

Looking for Something Specific?

Looking for Something Specific?

30+ Years' Experience

40,000+ Projects Completed

1500+ Clients Served

80+ NPS Score

Testimonials

Frequently Asked Questions

The inspection frequency depends on factors such as asset type, service conditions, regulatory requirements and risk profile. Kova can recommend an optimal inspection schedule after conducting a criticality analysis and reviewing historical performance data.

By aligning inspections, documentation and maintenance activities with CSA, ASME, API and other relevant standards, Kova ensures that your facility consistently meets regulatory requirements and is prepared for audits or compliance checks at any time.

We use a variety of methods, including visual inspections, non-destructive testing (NDT) like magnetic particle testing, liquid penetrant testing, ultrasonic thickness measurement and welding inspections, as well as QA/QC verification, load testing and material identification.

We use a combination of historical inspection data, performance monitoring, operational stress analysis and predictive modeling to track degradation rates and forecast future performance — helping you plan for repairs, upgrades or replacements well in advance.

Yes. We perform Fitness-for-Service (FFS) assessments to determine if degraded or damaged assets can safely continue operating or if repairs or replacements are necessary. This helps clients make informed decisions based on engineering analysis rather than assumptions.

Yes. Our team has extensive experience working with older facilities and legacy equipment, where original documentation may be missing or historical inspection data is limited. We apply reverse engineering, material identification and baseline inspection techniques to establish reliable integrity baselines for aging assets.